Image Source: Google

In today’s fast-paced world, keeping up with the latest fashion trends can be a challenge. Whether you are a clothing designer, a fashion enthusiast, or someone who wants to give your wardrobe a fresh new look, the key to staying ahead in the fashion game is investing in innovative technologies. DTF heat press technology is one such technology that is revolutionizing how we create custom apparel.

The Basics of DTF Heat Press Technology

DTF heat press technology is a game-changer in the world of custom apparel. It involves printing designs onto a special film which is then transferred onto the fabric using a heat press machine. This innovative technology offers a wide range of benefits that can take your wardrobe to the next level.

Benefits of DTF Heat Press Technology

- Vibrant and Detailed Prints: DTF heat press technology allows for high-quality, vibrant, and detailed prints that are long-lasting and resistant to fading. This means that your custom apparel will look fresh and new for a long time.

- Versatility: DTF heat press technology is versatile and can be used to print on a wide range of fabrics, including cotton, polyester, and blends. This gives you the freedom to create custom apparel for any occasion.

- Cost-Effective: DTF heat press technology is a cost-effective method of creating custom apparel. It eliminates the need for screens or plates, making it a more affordable option for small-scale production.

- Easy to Use: DTF heat press technology is easy to use and requires minimal training. This means that you can start creating custom apparel right away, without having to invest in expensive equipment or hire specialized staff.

How DTF Heat Press Technology Works

The process of using DTF heat press technology is simple. Here’s how it works:

Step 1: Design Creation

The first step in using DTF heat press technology is to create a design using graphic design software. Once the design is ready, it is printed onto a special DTF film using a printer with DTF ink.

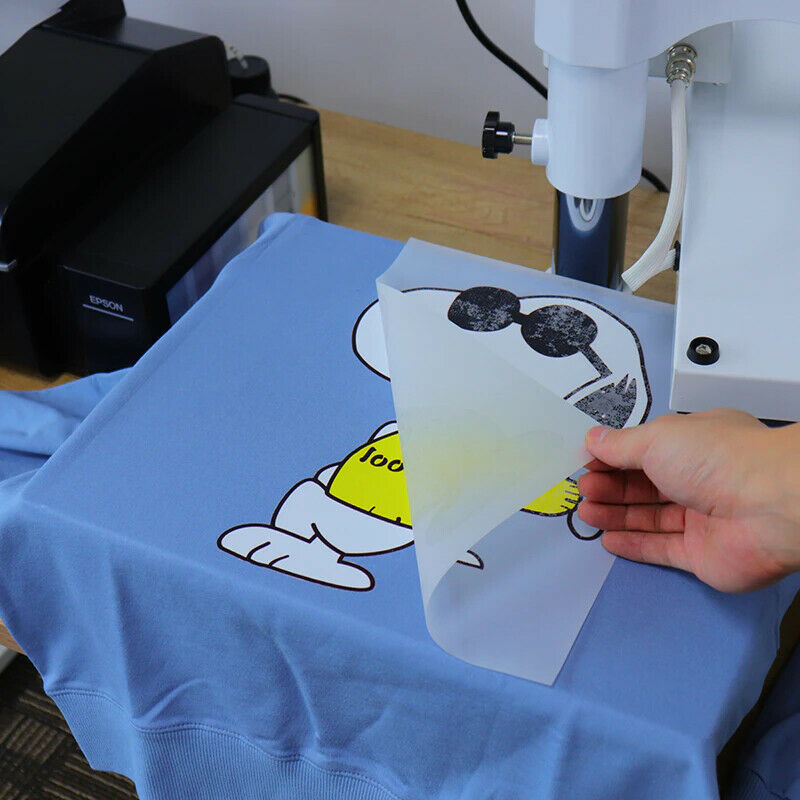

Step 2: Film Transfer

After the design is printed onto the DTF film, it is then transferred onto the fabric using a heat press machine. The heat press machine applies heat and pressure to the film, causing the design to transfer onto the fabric.

Step 3: Peeling Off

Once the design has been transferred onto the fabric, the DTF film is peeled off, leaving behind a vibrant and detailed print on the fabric. The print is now ready to be worn and enjoyed!

Applications of DTF Heat Press Technology

DTF heat press technology can be used in a variety of applications to create custom apparel for different purposes. Some common applications of DTF heat press technology include:

Custom T-Shirts

DTF heat press technology can be used to create custom t-shirts with vibrant and detailed prints. Whether you are looking to create a one-of-a-kind t-shirt for yourself or your business, DTF heat press technology has got you covered.

Merchandise

Businesses can use DTF heat press technology to create custom merchandise such as hats, bags, and other accessories. This is a great way to promote your brand and create unique products that stand out from the competition.

Sports Apparel

Athletes and sports teams can benefit from DTF heat press technology to create custom sports apparel. Whether it’s jerseys, uniforms, or fan gear, DTF heat press technology can help you create high-quality and durable apparel for any sport.

Conclusion

Revolutionize your wardrobe and take your custom apparel to the next level with DTF heat press technology. This innovative technology offers a wide range of benefits, including vibrant and detailed prints, versatility, cost-effectiveness, and ease of use. Whether you are a clothing designer, a business owner, or someone who wants to create unique apparel for personal use, DTF heat press technology is the way to go.